ABOUT US

Product

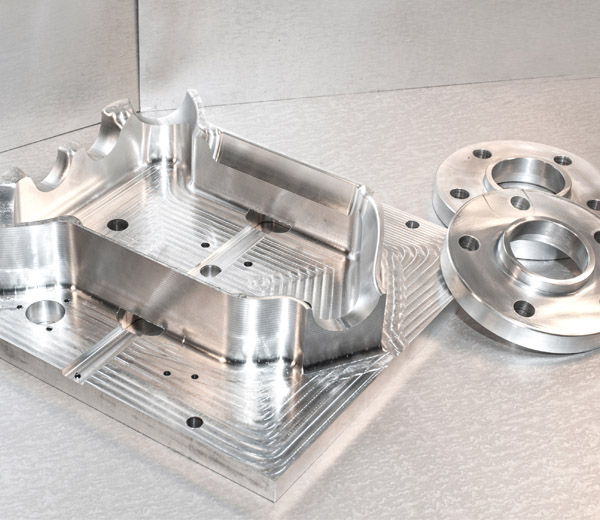

Professional die-casting mold manufacturer

Application

The product sells well all over the country and is exported with matching products, deeply trusted by users.

-

Auto parts

Traditional automotive components: core components such as engine cylinder block, gearbox housing, clutch housing, etc. are manufactured using die-casting technology, utilizing the high thermal conductivity and precision forming ability of aluminum alloy materials to enhance performance. Innovation of new energy vehicles: Key components such as battery cases and charging station casings are achieved through large-scale integrated die-casting technology to achieve lightweighting and strength improvement. This type of mold requires the integration of cooling pipelines and core pulling mechanisms to optimize thermal balance and extend its service life by 34. Body structural components: wheel hub, support

View details -

Electronic and Electrical Appliances

The trend towards miniaturization and lightweight electronic products has made die-casting molds the preferred solution for precision manufacturing. Consumer electronics: Components such as phone/laptop casings and heat sinks are made of zinc alloy or magnesium alloy die-casting, which combines aesthetics and heat dissipation performance. Communication infrastructure: Components such as 5G base station radiators and connectors are die cast to achieve complex structures and efficient heat dissipation, supporting the stable operation of high-speed data transmission equipment.

View details -

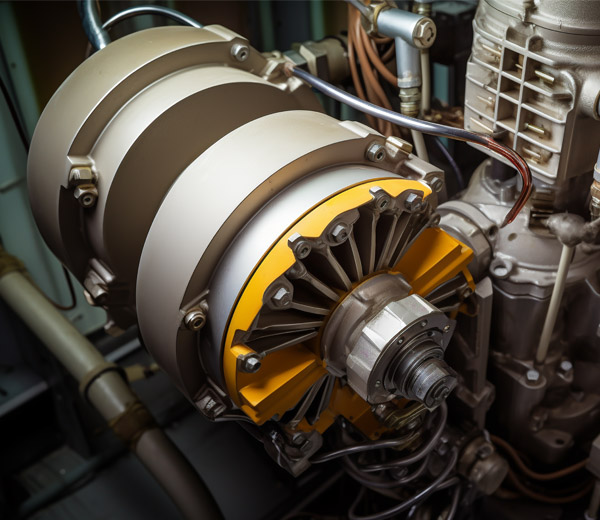

Mechanical Engineering

In the field of heavy industry, die-casting molds support high-precision and high-strength equipment manufacturing. Electric motors and pump valves: Industrial motor casings, pump casings, valve bodies, and other components need to withstand high pressure and high temperature environments. Die casting processes optimize materials (such as copper alloys) and structural design to ensure the reliability and durability of equipment. Instrumentation: Precision instrument parts require extremely high dimensional accuracy and surface quality. Die casting molds achieve micrometer level tolerance control through CNC machining and mold flow analysis. New energy equipment: emerging applications such as photovoltaic inverter radiators and wind turbine components, accelerating the development of the green energy industry through the rapid prototyping capability of die-casting.

View details -

Aerospace

With the advancement of technology, die-casting molds are breaking through traditional boundaries and penetrating into higher value-added fields. Aerospace: Magnesium alloy die-casting parts are used for non load bearing structural components such as aircraft seat brackets, balancing lightweight and cost control.

View details -

Modelling

The flexibility of die-casting technology and its adaptability to small batch production make it a powerful assistant for the creative industry. Alloy model car: By using zinc alloy die-casting to restore fine body details, combined with coating technology to create collectible models. Toy parts: Small precision parts such as gears and joints utilize the high efficiency and low cost advantages of hot chamber die casting to meet the needs of large-scale production.

View details -

Kitchen and Bathing

Kitchen and bathroom supplies: faucet components, shower housings, etc. utilize the high wear resistance and antibacterial properties of copper alloy to meet the needs of frequent use scenarios.

View details -

Smart Home Accessories

Smart home accessories: Door locks, sensor housings, and other products rely on the surface smoothness and consistency of die-casting to enhance user experience.

View details

Product

Professional die-casting mold manufacturer

News

Get to know the latest news from Sunrise

2025

08 -19

2025

08 -19

2025

08 -19

2025

08 -19

Users can call for free consultation if they encounter any problems during use